Stanton Bikes- CNC Rear Triangle

Stanton Bikes are a bicycle company specialising in hand built hardtail and full suspension mountain bikes. Their UK manufactured Switch full suspension range that combines a Reynolds steel front end with an aluminium rear triangle has sold large volumes globally and received many accolades within the industry; with Enduro mtb magazine describing the bike as “an engineers dream, with tight tolerances and innovative features.”

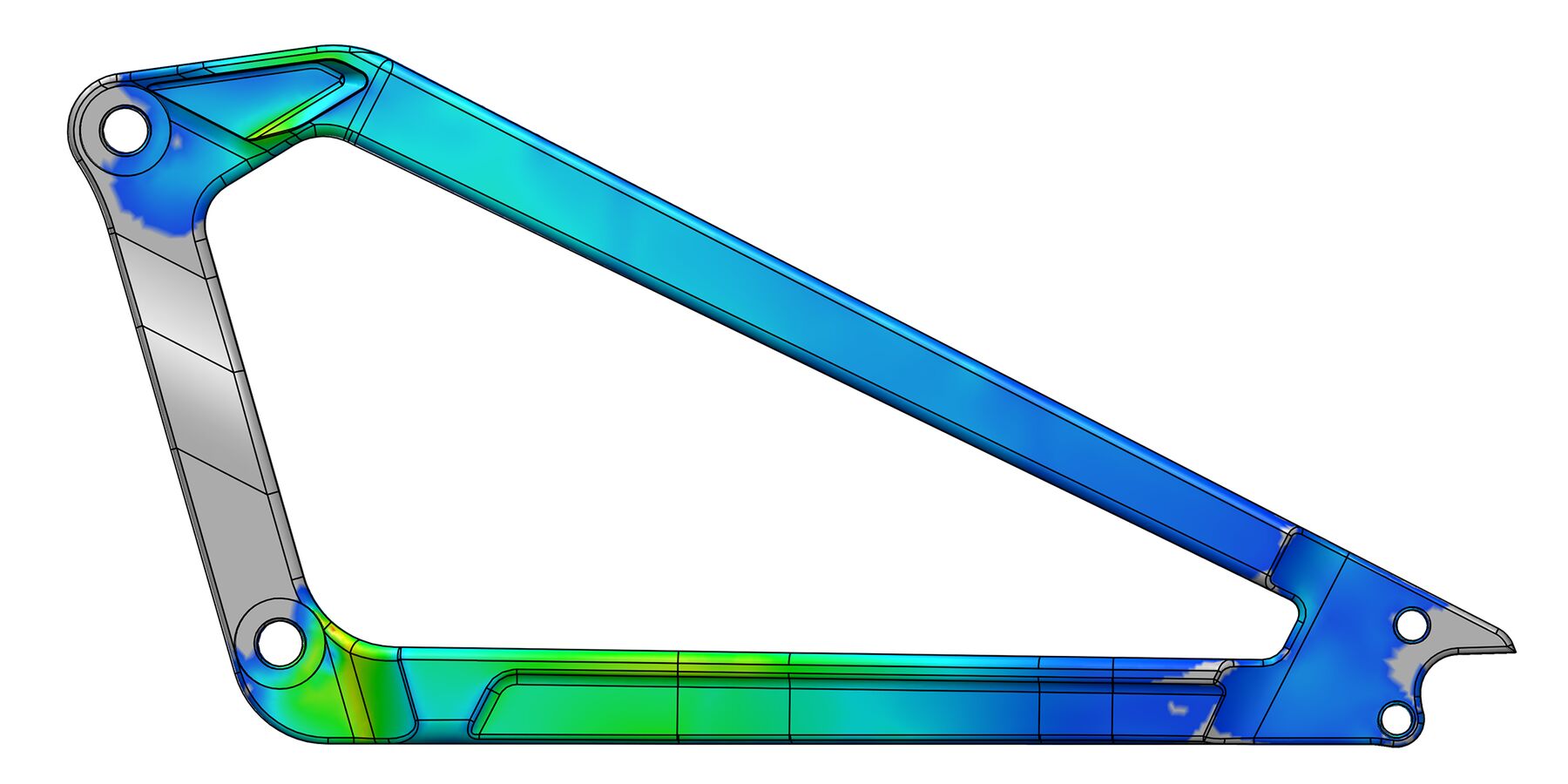

We collaborated with Stanton Bikes to design and develop a series of fully CNC machined rear triangles for their critically acclaimed Switch FS range. One of the main aims of the project was to reduce the extensive number of manufacturing processes required to produce a conventional aluminium welded assembly. The product followed our iterative design and development process, with the prototype currently undergoing extensive real world and ISO testing. We then use rider feedback and test result data to further optimise the design in FEA, striving for the perfect balance of stiffness and strength to weight that is tuned for product function and user experience.

Some of the key services and tools used within this project are detailed below:

- Design specification

- Conceptualisation

- Photorealistic rendering

- Lifecycle and sustainability

- Hand sketches

- Finite element analysis (FEA)

- Material selection

- Weight saving analysis

- Detailed design

- 3D CAD

- Engineering drawings

- Technical report writing

let’s work together